This is the AirDog II-4G fuel system for the 1992-2000 Chevy/GMC 6.5L Diesel. This fuel system replaces your factory low pressure frame rail mounted pump. This diesel lift pump mounts to the frame rail using the supplied sandwich plate mounting system. The suction side hooks up to the factory suction line. The pressure side connects directly to the factory injection pump feed line on the frame. The AirDog Air/Vapor return is sent back to the tank through a filler neck tee.

This is a 165GPH (Gallon Per Hour) lift pump system.

This is a 100GPH (Gallon Per Hour) lift pump system.

Quality Engineered to Remove entrained Air/Vapor, water, and particulates down to 2 micron from diesel fuel.

The advanced 4G technology offers protection and performance like never before! Our patented air separation, along with a water separator and fuel filter makes sure your expensive injection system components get all the clean fuel they need. The AirDog® II-4G also overcomes loss of power due to driving in higher altitudes.

The AirDog® II-4G System Improves Engine Performance by eliminating spray pattern disruption due to air entering the system. This allows the engine to keep its designed injection timing which allows a more complete burn of the fuel entering the cylinder. This increases overall engine efficiency across the power and torque range!

Unlike many of our competitors and older products of our own, the 4G offers features to make it more durable than any other brushed DC motor system on the market!

The technology of the AirDog ® II-4G system resides in the secrets of the 4G motor. The advanced features of the motor provide protection and efficiency. With the new design, circulating fuel is kept separate from the electric motor. This is done two ways. First, the motor head is lengthened to include a cavity which safeguards the motor from circulating fuel. Second, with the use of a specially designed intermediate pump shaft, fuel is moved away from the electric motor. Lastly, the self-aligning, low amperage motor eliminates wear and tear, internal vibration, and reduces noise.

The installation of any AirDog/Raptor system has been designed with the customer in mind. We know not everyone has special tools or fabrication skills, so we made the installation as easy as possible with basic hand tools and the, occasional, power drill. The quick-connect fittings and fuel lines make this a true plug and go installation, reducing the overall installation time. Our step-by-step manual outlines each process of the installation and is accompanied by visual guides to aid your progress.

All-Incluesive Installation Kit Includes:

AirDog ® II-4G Fuel Air Separation System with Fuel Demand Flow Technology and Enhanced Features

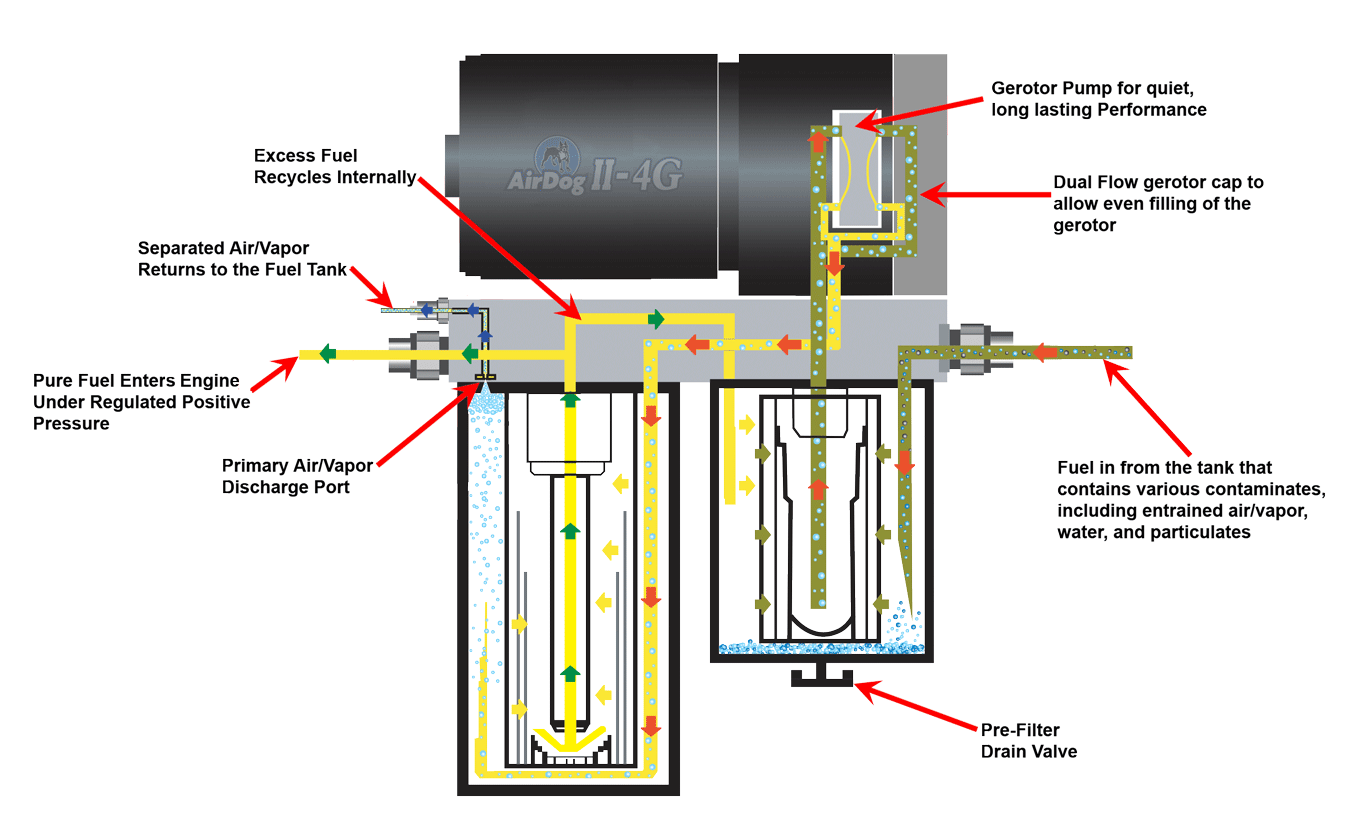

AirDog ® II-4G is designed to operate at flows and pressures beyond the maximum requirements of the engine. It receives fuel under vacuum from the fuel tank containing entrained air/vapor, particulate contaminates and unknown quantities of water.

The fuel passes through the water separator which removes the large particulate contaminates that could damage or jam the gerotor fuel pump. The fuel with only entrained air/vapor and tiny particulate contaminates remaining, enters the fuel pump.

The fuel, now under positive pressure flow, enters the fuel filter. As the fuel passes through the filter media and the remaining particulate contaminates are caught and contained, the entrained air/vapor is also separated. Through the positive fuel air separation features of the patented AirDog ® II-4G the separated air/vapor is discharged from the filter and back to the fuel tank through the Primary Air/Vapor Discharge Port.

The fuel passing through the filter media is now free of contaminates and power robbing air/vapor. At pressures and flows able to meet the needs of the engine, it exits the fuel filter through two passageways. First, the fuel for the engine passes into the fuel pickup tube and on to the engine. Then, the excess fuel not needed by the engine recycles internally through the pressure regulator back to the water separator.